Certech Group, headquartered in Italy, is an international network of companies operating in ceramics, rubber, and industrial services. Its core, Certech S.p.A., produces pumps, grinding solutions, and tailored equipment, supported by Eurorubber, Vibrotech, Novatech, and Elema. With branches in Spain, Mexico, and the USA, the Group ensures global reach and service. Focused on efficiency, reliability, and sustainability, Certech invests in R&D to deliver innovative technologies, technical compounds, and services, building lasting partnerships worldwide.

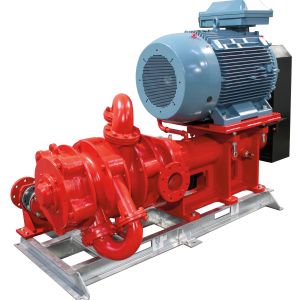

Product 1: Foto Davanti

The 3PowerFlow centrifugal pump is a high-performance solution specifically designed for feeding spray-driers in industrial applications. Engineered with a triple-body construction, it delivers exceptional efficiency, reliability, and flexibility, replacing the work of multiple piston pumps with a single robust unit. With a flow capacity ranging from 6 m³/h to 120 m³/h and a maximum closed pressure of 22 bar, the pump is suitable for a wide range of operational needs. Its bodies and impellers are manufactured from anti-abrasive superalloy chrome, ensuring durability even under demanding conditions. The suction inlet is strategically positioned to prevent direct contact between the slurry and the mechanical seal. This seal, made oftungsten carbide and protected by a pressurized barrier chamber, is water-drained to maximize longevity and reliability.The pump operates on a horizontal axle with sealed bearings, lubricated in an oil bath for smooth and continuous performance. Drive coupling is achieved through V-belts and pulleys with protective guards, though direct coaxial coupling options are also available. The sturdy base frame is constructed from hot-galvanized steel, providing stability and resistanceagainst corrosion. Key advantages include reduced maintenance requirements, lower water consumption for seal flushing (just 2–5 liters per minute), and consistent operating pressure that ensures uniform humidity and granulometry at thespray-drier outlet. This stability results in more spherical powder grains, improving press loading efficiency.By consolidating multiple pump functions into a single unit, the 3PowerFlow reduces space requirements, simplifies maintenance, and minimizes downtime. Additionally, during customer pump servicing at Certech facilities, a temporary replacement pump is provided to guarantee uninterrupted operations. The 3PowerFlow stands out as a modern, space-saving, and reliable pumping solution, combining advanced materials, intelligent design, and operational flexibility to meet the most demanding spray-drying processes.

Product 2: Alurubber Lining

ALURUBBER is an innovative composite lining system designed for grindingmills, combining the flexibility of rubber with the extreme hardness of high-density alumina. Developed and patented by Certech S.p.A., ALURUBBER represents a breakthrough in wear-resistant linings, delivering superior protection, efficiency, and durability compared to traditional rubber linings The concept was first patented in 1996, making it the world’s first composite rubber-alumina lining. Today, ALURUBBER is the result of decades of research, advanced testing, and engineering innovation, reinvented with cutting-edge techniques to meet modern industrial demands The system is composed of flat-profile rubber pieces that incorporate closely positioned alumina cylinders of exceptional quality and density. This configuration maximizes the surface area covered by alumina, creating a highly durable and fully protected lining. The circular shape of the alumina cylinders and their reduced contact surface eliminate the risk of breakage, a common issue with larger rectangular ceramic elements ALURUBBER can be installed in all types of continuous and modular mills,including critical areas such as the feed head and the cylinder-head connection, where wear is most intense. Thanks to its modular structure, it offers the flexibility of traditional rubber linings while providing outstanding resistance to abrasive wear.Key advantages include:

Lower grinding body consumption, extending the lifecycle of milling media By combining strength, flexibility, and energy efficiency, ALURUBBER sets a new standard in mill lining technology. It ensures longer service life, reduced maintenance costs, and consistent performance, making it the ideal solution for companies seeking high-quality, reliable, and cost-effective grinding protection. Unmatched abrasion resistance due to the hardness of alumina elements. Reduced energy consumption of the mill, optimizing operational efficiency.

Product 3: Whi Filter

The WHI Filter is a state-of-the-art high-intensity, high-gradient magnetic filter designed to remove iron impurities from slurry and ceramic glazes. Its advanced magnetizing matrix system amplifies the base magnetic field produced by the powerful coil, ensuring effective capture of even the finest ferromagnetic and paramagnetic particles. Available in different models (90/3, 200/7, 250/11, 400/20), the WHI Filter offers magnetic intensities up to 35,000 Gauss, making it one of the mostpowerful filtration systems in its category. Depending on the configuration, it can process flow rates ranging from 500 to 50,000 liters per hour, guaranteeing versatility for both small and large-scale operations. The filter is equipped with electropneumatic valves and a dedicated electrical cabinet that enable automatic counter-current cleaning,minimizing downtime and reducing manual maintenance. Additionally, the system includes a magnetic channel for wash water cleaning and a dedicated cabin for grid washing, which typically requires only weeklyintervention.Key features include:

Stainless steel construction for durability and corrosion resistance.By ensuring a consistently high level of purity in slurries and glazes, the WHI Filter enhances the quality of ceramic products, reduces defects, and optimizes production efficiency. Its high throughput capacity and low-maintenance operation make it an essential solution for modern ceramic manufacturing plants aiming to maintain top-quality standards whilelowering operating costs. The WHI Filter represents the ideal balance between technological innovation, reliability, and productivity in ceramic filtration system Superior filtration efficiency with high-gradient magnetic technology. Automatic cleaning system for continuous operation and reduced maintenance. Compact and robust design, with models covering different production needs.