Keramischer OFENBAU GmbH is a leading German manufacturer of industrial kilns for the ceramics industry. With decades of experience and more than 500 kiln plants installed worldwide, we deliver tailor-made solutions for a broad spectrum of applications – from sanitaryware, tableware and structural ceramics to advanced ceramics such as fuel cells and high-voltage insulators. Our core strength lies in combining proven, reliable technology with forward-looking innovation. For new plants, we provide tunnel, shuttle and roller kilns engineered for maximum energy efficiency, yield, precision, and product quality. For existing plants, our long-established retrofit expertise enables customers to achieve substantial energy savings and CO₂ reductions without replacing their assets – often with short downtimes and rapid return on investment. Keramischer OFENBAU is also at the forefront of next-generation technologies: fully electric kilns, hydrogen-ready solutions, and our proprietary EnerViT firing system, which has demonstrated energy savings of up to 50 % in retrofits while being fully H₂ ready. This comprehensive portfolio allows our customers to prepare for the energy transition with technologies that are both economically viable and environmentally sound. As a trusted and reliable partner, we are committed to supporting customers worldwide with engineering expertise, flexible supply chains, and long-term service. We invite you to meet us at ASEAN Ceramics and see for yourself how our solutions can make ceramic production more efficient, sustainable, and future-proof.

Product Description

Product 1: Shuttle Klin

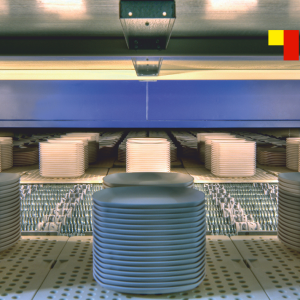

Keramischer OFENBAU shuttle kilns have long been recognised as a guarantee of outstanding firing quality for first firing, refiring and decoration. Their excellent temperature uniformity, combined with low specific energy consumption, has made them a proven solution for decades in many ceramic industries. As highly flexible discontinuous kilns, they are capable of meeting the most demanding requirements across a wide variety of products, including: - sanitaryware - tableware - structural ceramics - advanced ceramics technical data at a glance: - firing temperature up to 1 800 °C - kiln volume up to 380 m³ - setting width up to 6.0 m - setting height up to 4.0 m - firing cycle 8 h to 180 h - capacity up to 40 000 t/a advantages: - single burner control and pulse-fired burners - low power consumption with frequency-controlled fans - heating: direct or indirect gas firing (various gas types) or electric heating - insulation: full fibre, lightweight brick or cordierite fibre combination - ProVis process visualisation with advanced control and analysis tools - LAMBDA control system for precise oxygen measurement for minimum consumption and combustion air - optional heat exchanger systems (e.g. air/water or air/air) Shuttle kilns from Keramischer OFENBAU combine robustness, versatility and process precision. Thanks to advanced control systems and a wide range of configuration options, they ensure consistent product quality, reliable operation and optimised energy use. With firing cycles adaptable from rapid to extended processes, they remain one of the most flexible and future-proof kiln technologies available today.

Product 2: Roller Kiln

Keramischer OFENBAU roller kilns are recognised worldwide as reliable, highly efficient firing systems for continuous ceramic production. Their outstanding temperature uniformity, combined with low energy consumption and minimal maintenance requirements, makes them a proven solution for a wide range of industries. As modular continuous kilns, they are ideally suited to the most demanding applications, including: - tableware - sanitaryware - structural ceramics - technical ceramics - SOFC and SOEC components - other advanced ceramics and special applications technical data at a glance: - setting width up to 3.0 m - 1–3 roller levels - firing temperature up to 1,650 °C - firing cycles 20 min to 48 h - heating: direct or indirect gas firing (various gas types) or electric heating - capacity up to 60,000 t/a advantages: - robust, maintenance-free roller drive - excellent temperature uniformity across the kiln cross-section - reduced energy consumption and shorter transit times - low power consumption with frequency-controlled fans - ProVis process visualisation with advanced control and analysis tools - product tracking system for PPS/MES integration - optional heat exchanger systems (e.g. air/water) - EnerViT system with up to 50 % energy savings Roller kilns from Keramischer OFENBAU stand for precision, durability and efficiency. Their modular design, combined with advanced control and energy-saving technologies, ensures consistently high product quality, optimised energy use and cost-effective production. With flexible cycle times and scalable configurations, they remain one of the most versatile and future-proof kiln solutions for the global ceramics industry.